Assignment #2

Assignment #2

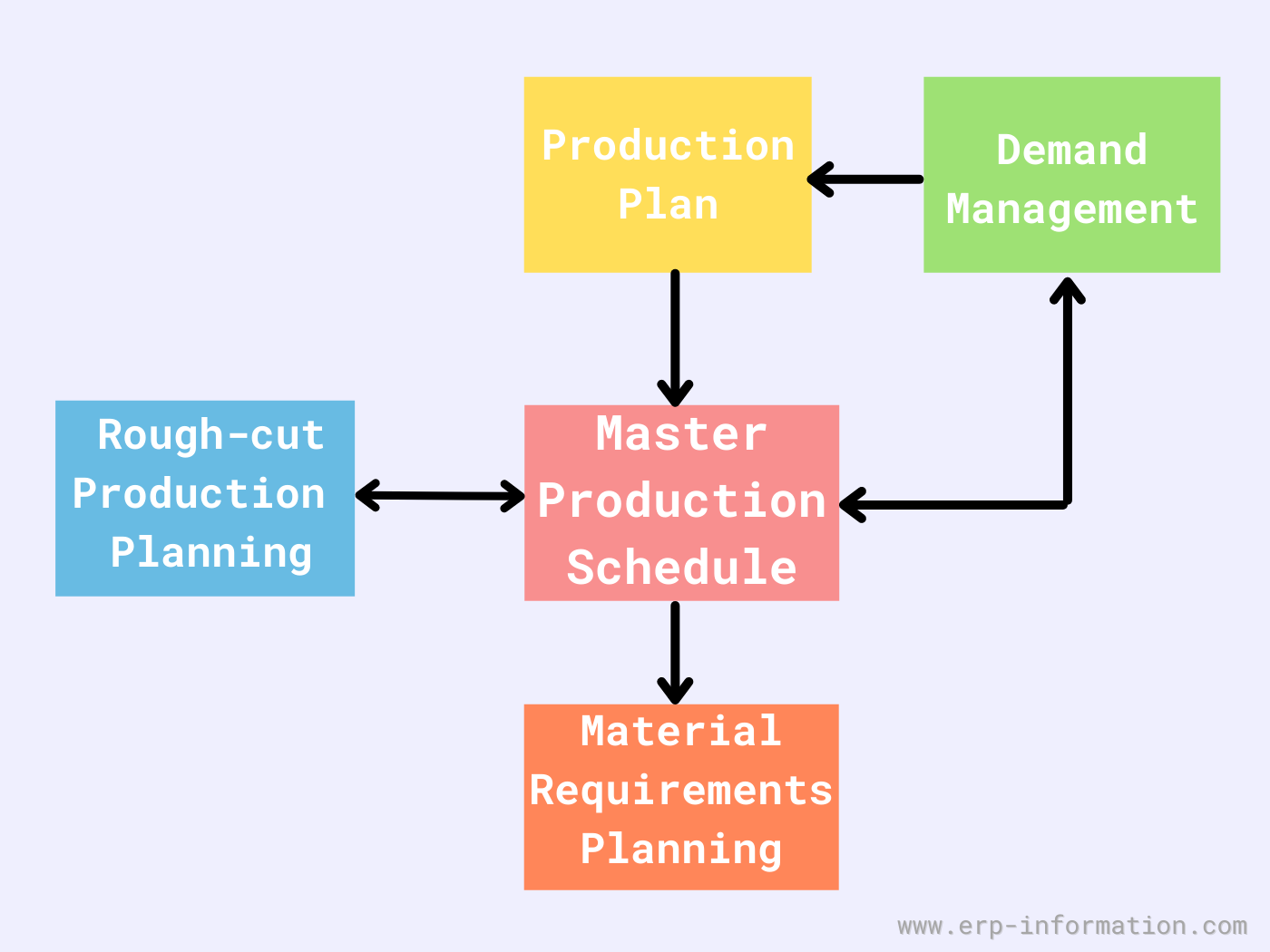

From my research,Master Production Schedule (MPS) is a master production schedule that defines the amount of each product that must be completed at different times and that must be used as a framework for planning to order raw materials and parts from external suppliers and set production schedules for parts to be produced.

In the operation of the production process, there will be a Master Production Schedule which will specify the type and amount of each product that must be produced to be completed at various specified intervals. Subsequently, these Master Production Schedules are converted to other raw material orders and parts production orders. For the production order, it will be used to create a production schedule for other parts. These activities must be carried out appropriately and in time with the due date. Products that are defined in the Master Production Schedule for the time period used in the Master Production Schedule can be months, weeks or days and are planned to cover approximately 2-4 months. Under the production capacity of the factory the volume of the product should not be greater than the factory's capacity to produce. The production capacity of this factory can be determined from the number of machines and labor that the factory has.

By using the implementation of the production process of the product by setting the Master Production Schedule, it makes it easier to produce the products according to the customers' needs, especially nowadays that online businesses are playing a very active role in the production market. As a result, the demand for that product increases, which makes the factory that produces the product have to set the master production schedule in order to be able to predict the production and the exact time of production in order to meet the needs of the customer. If the system is not managed well, it will damage other systems that have to run after this part of production and will affect sales and customer needs.

ความคิดเห็น

แสดงความคิดเห็น